Hydraulic power unit and control electronics to cover power outages

Steel Structure that is hot-dip galvanized and AISI 316 grade stainless steel

Suitable for all weather conditions between -15 degrees celsius to +65 degrees Celsius

Optional Accessories for added benefits and individual requirements

What are Optima HRB-HS Bollards?

HRB-HS is a series of hydraulic rising bollards from Optima that are made for high-security vehicle entries. The driving system is hydraulic, although manual hand pumps may be used to manually lower or raise the bollard in the event of a power outage. Every type of card reader, biometric reader (such as fingerprint or hand shape), radio control, on/off key switch, etc. may all perform the raise/lower function with the aid of PLC-controlled electronics. Additionally, the system can incorporate safety add-ons such as photocells, inductive loop detectors, flashing lights, or red/green lights. The Optima HRB-HS series hydraulic retractable bollards are made for high-security vehicle entries, military, commercial, industrial, governmental, and street areas where vehicular traffic is prohibited during specific hours of the day.

Characteristic Features

-

- Height when raised: 400-1200 mm

- Environmental durability: 316 stainless steel sleeve, underground parts are hot dip galvanized

- Axle load: 50 tons

- Structure: Heavy duty

- Top plate: Sand-blasted aluminium with flashing lights around

- Type of steel: S275 (inner core), finishing 316 stainless steel sleeve

- Traffic light: Red/green LED, 200 mm diameter, steel post 2 m height and electrostatic powder coated

- Power:380 V, 3 Phase, 50-60 Hz (or 220 V/ 440 V etc., three-phase, 50-60 Hz optional by a transformer)

- Power failure: Manual hand pump, (or Hydraulic accumulator, DC motor and batteries or UPS (optional)

- Speed: From 1 bollard to 4 bollards per hydraulic unit: 3-5 s (1.5 s Emergency Raise) From 5 bollards to 6 bollards per hydraulic unit: 5-7 s (2 s Emergency Raise) From 7 bollards to 8 bollards per hydraulic unit: 8-12 s (3 s Emergency Raise)

- Desktop keyboard: Raise, lower, emergency stop, key operated, ‘keyboard in use’ light indicator

- Extra I/O at the PLC: Enough I/O’s to connect any card reader, extra override keyboard etc. later on

- Proximity Sensor: Available to sense the position of the bollard

- Dual vehicle safety loop detector: This detector is used for safety

- Motor Power: Min 4 KW, 1500 rpm

- Environmental conditions: -25 °C and +65 °C, 95 % non-condensing humidity

- Environmental conditions (optional): -40 °C and +70 °C, 95% non-condensing humidity

Hydraulic Power Unit and Control Electronics:

All hydraulic components are tested at 250 bars. In case of power failure, the bollard can be raised and lowered with the help of a manual pump. Bollard raise/lower time is 3-5 seconds. The emergency fast rise is 1.5 seconds. Coolers or heaters can be integrated for extreme weather conditions. Microelectronics control the bollards. Two push buttons operate keyboards and one desktop. AC electric is driven by a contactor and protected by a thermic breaker. All cables are colour coded. LED lights are located at top of the bollard.

Steel Structure:

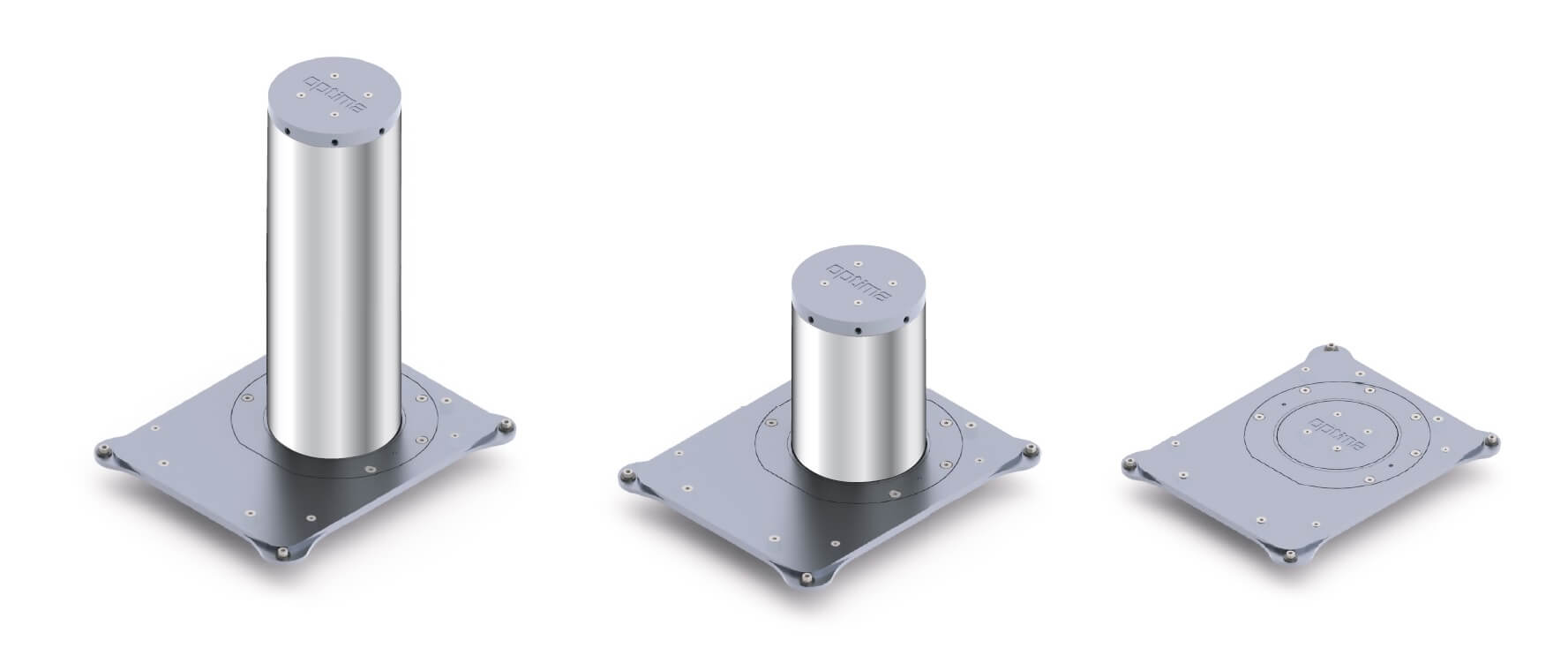

The raising section of the bollards is 219 mm (options available) in diameter and raised height is 80 cm. The bollard is made of a special type of high-grade stainless steel that is galvanized and has a flashing light on top.

Hydraulic Power Unit and Control Electronics:

All hydraulic components are tested at 250 bars. In case of power failure, the bollard can be raised and lowered with the help of a manual pump. Bollard raise/lower time is 3-5 seconds. The emergency fast rise is 1.5 seconds. Coolers or heaters can be integrated for extreme weather conditions. Microelectronics control the bollards. Two push buttons operate keyboards and one desktop. AC electric is driven by a contactor and protected by a thermic breaker. All cables are colour coded. LED lights are located at top of the bollard.

Steel Structure:

The raising section of the bollards is 219 mm (options available) in diameter and raised height is 80 cm. The bollard is made of a special type of high-grade stainless steel that is galvanized and has a flashing light on top.

Environmental conditions and Power Requirements:

The bollard operates efficiently in all weather conditions between -15 degrees celsius to +65 degrees Celsius. It is also operable in 95% non-condensing humidity, 380V, 3 phase, and 50-60 Hz. which makes this bollard versatile.

Optional accessories included with Optima HRB-HS Bollards

-

- Red/green traffic lights with steel pole

- Dual vehicle safety loop detector

- Safety photocell

- Stand and casing for safety photocell

- Protective construction around the drive unit

- Hydraulic accumulator

- Transformer to convert the power

- Uninterrupted power supply (UPS)

- DC motor and pump with batteries

- Submersible drainage pump

- Wrong way alarm

- High-speed alarm

- SCADA or any control system

What models are available with Optima HRB-HS Bollards?

-

- Raised Height: 400-1200 mm

- Diameter:168/219/273/324/355 mm

- Standard Height: 800 mm

- Groups: from 1 bollard to 4 bollards per hydraulic power unit

- Groups: from 5 bollards to 6 bollards per hydraulic power unit

- Groups: from 7 bollards to 8 bollards per hydraulic power unit

Interested in Optima’s HRB-HS Bollards?

Contact Stebilex for services – supply, installation and maintenance of Optima’s HRB-HS Bollards